- お役立ち記事

- How to Proceed with Manufacturing DX

How to Proceed with Manufacturing DX

In today’s rapidly evolving manufacturing landscape, digital transformation (DX) has become a crucial strategy for companies looking to enhance efficiency, reduce costs, and stay competitive. Through the adoption of innovative technologies such as AI and iPaaS, manufacturers can streamline processes, improve operations, and drive business growth.

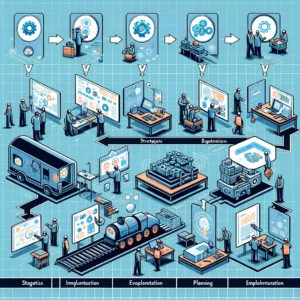

Steps of prosed with manufacturing DX

I am here to guide you on how to proceed with manufacturing DX effectively.

1. Understanding the Needs: The first step in embarking on a successful DX journey is to identify the pain points and challenges faced by your manufacturing operations. Conduct a comprehensive assessment of your current processes, technology infrastructure, and business objectives to determine where DX can make the most significant impact.

2. Setting Clear Goals: Define clear and measurable goals for your DX initiative. Whether it is improving production efficiency, reducing time to market, optimizing supply chain operations, or enhancing product quality, having specific objectives will help guide your DX strategy and track progress.

3. Leveraging AI and iPaaS: AI technology plays a critical role in transforming manufacturing operations by enabling predictive maintenance, demand forecasting, quality control, and process automation. Integrated Platforms as a Service (iPaaS) solutions facilitate seamless data integration and workflow automation across disparate systems, enhancing operational efficiency and collaboration.

4. Partnering with Experts: Collaborate with experienced consultants and technology providers specializing in manufacturing DX to leverage their expertise and best practices. These partnerships can accelerate the implementation of DX initiatives, ensure a smooth transition, and maximize the value generated from technology investments.

5. Developing a Roadmap: Create a detailed roadmap outlining the key milestones, timelines, and resource requirements for implementing DX initiatives. Prioritize projects based on their impact and complexity, and develop a phased approach to ensure a systematic and successful deployment of DX solutions.

6. Employee Training and Change Management: DX initiatives require a cultural shift within the organization, where employees embrace new technologies and ways of working. Provide comprehensive training programs to upskill your workforce and involve them in the change management process to ensure smooth adoption of DX solutions.

7. Monitoring and Continuous Improvement: Implement robust monitoring and evaluation mechanisms to track the performance of DX initiatives against predefined KPIs. Regularly review and analyze the results to identify areas for improvement and optimization, ensuring ongoing success and ROI from your DX investments.

By following these steps and leveraging the expertise of industry professionals, you can effectively proceed with manufacturing DX and unlock the full potential of digital transformation for your organization. Stay ahead of the curve, drive innovation, and position your company for sustainable growth in the competitive manufacturing landscape.