- お役立ち記事

- A Practical Guide to the 5S Method to Improve Productivity in Manufacturing through Organizing

A Practical Guide to the 5S Method to Improve Productivity in Manufacturing through Organizing

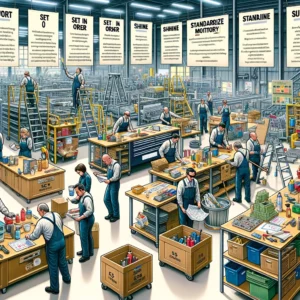

In the fast-paced world of manufacturing, efficiency is key to success. One proven method for improving productivity and streamlining operations is the 5S methodology. Originally derived from five Japanese words that start with ‘S’ and translate to Sort, Set in order, Shine, Standardize, and Sustain, the 5S method is a systematic approach to organizing the workplace for efficiency and effectiveness.

the 5S method

1. Sort: Keep What You Need, Discard What You Don’t

The first step in implementing the 5S method is to sort through all items in the workspace. Identify necessary tools, materials, and equipment, and remove anything that is unnecessary or redundant. By decluttering the workspace, you reduce the time spent searching for items, thus improving efficiency.

2. Set in Order: Organize Everything in its Right Place

With unnecessary items removed, the next step is to organize the remaining items in a logical and efficient manner. Designate specific locations for tools and supplies, and clearly label storage areas. By ensuring that everything has a designated place, you reduce the chances of misplaced items and waste less time searching for them.

3. Shine: Keep the Workplace Clean and Tidy

A clean workspace is essential for efficient operations. Regularly clean and maintain the workspace to remove dirt, dust, and debris. Encourage employees to take pride in their work environment and instill a culture of cleanliness. A clean workspace not only improves safety but also boosts employee morale and productivity.

4. Standardize: Establish Consistent Procedures and Practices

To maintain the improvements made through the 5S method, it is crucial to standardize processes and procedures. Develop clear guidelines and protocols for organizing the workspace, conducting cleaning activities, and maintaining order. Standardization ensures that everyone follows the same practices, leading to consistency and efficiency.

5. Sustain: Make 5S a Habit

The final step in the 5S method is to sustain the improvements made. Encourage a culture of continuous improvement by regularly reviewing and auditing the workspace. Engage employees in the process and seek their feedback on how to further enhance efficiency. By making 5S a habit, you ensure that the benefits of organization and productivity are long-lasting.

By implementing the 5S method in your manufacturing operations, you can achieve greater efficiency, improved productivity, and a more organized workplace. Start with small steps, involve your team, and make 5S a part of your daily routine. The results will speak for themselves, and you’ll soon see a positive impact on your bottom line.