- お役立ち記事

- Application of AI and Automation to Manufacturing

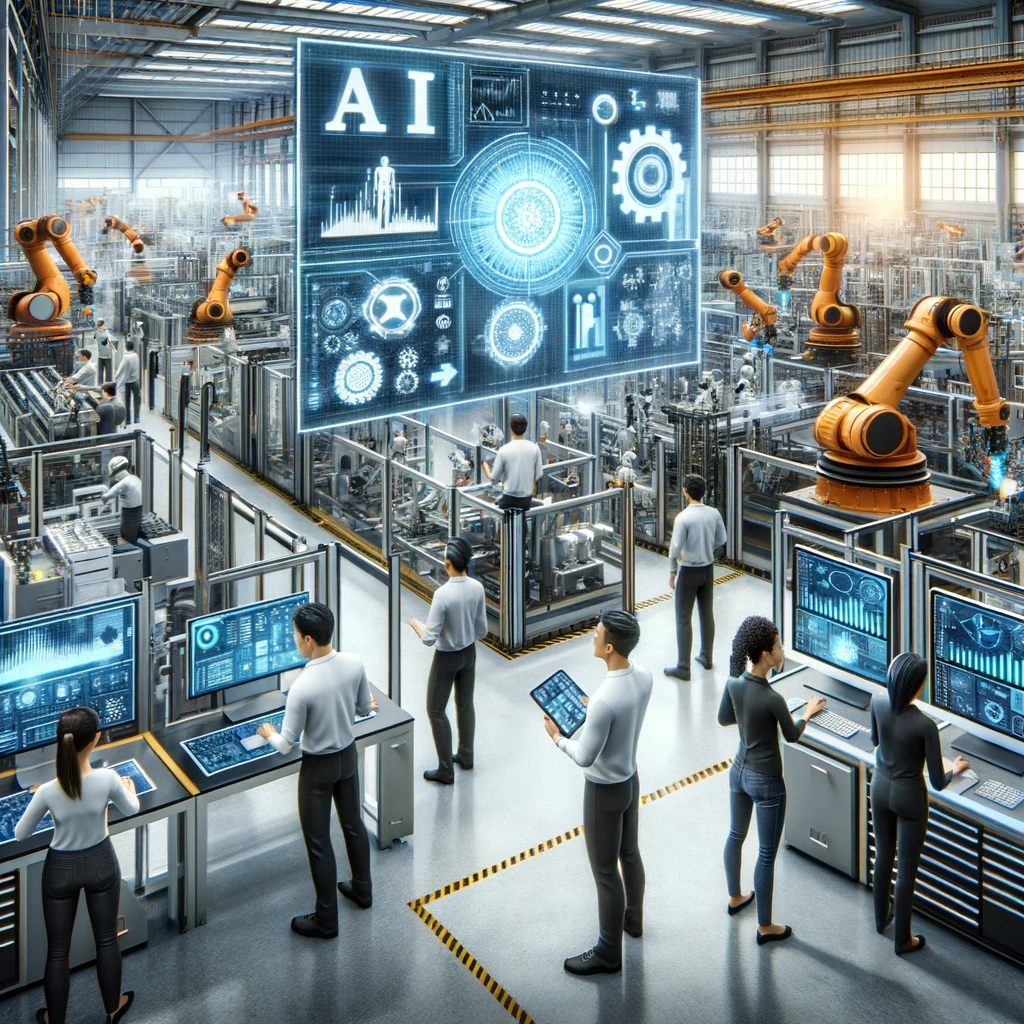

Application of AI and Automation to Manufacturing

Artificial intelligence (AI) and automation are revolutionizing manufacturing. As robots and computers get smarter, they are able to do more of the work that used to require human employees. This increases production and reduces costs. It also allows factories to work 24 hours a day without stopping. AI and automation are being used in many different ways in manufacturing.

目次

Some key ways AI and automation are applied to manufacturing include:

Robot assembly lines: Many factories now use robots to build products on assembly lines. Robots can lift heavy parts, weld pieces together, and perform other repetitive tasks more quickly and precisely than humans. For example, car factories use robots to help build vehicle bodies and engines. This allows cars to be produced in very high volumes.

Automated quality control: In many factories, robots and computer vision systems help inspect products to ensure consistent quality. Cameras can examine each item and verify measurements and that it was built correctly. Any defects can be identified quickly. This type of automated quality control helps manufacturers reduce errors and catch problems early.

Predictive maintenance: Manufacturing equipment like machines can have sensors added that monitor performance data over time. AI analyzes this equipment health monitoring data to predict when maintenance may be needed before breakdowns occur. This predictive maintenance helps manufacturers avoid unexpected downtime and increase uptime of their production equipment.

3D printing and additive manufacturing: 3D printers powered by AI-optimized software can print objects directly from 3D model files without tooling or manufacturing setup. This provides flexibility to produce custom parts on demand. It also reduces material waste compared to traditional milling or molding. Additive manufacturing has the potential to reshape supply chains by decentralizing production.

Collaborative robots: Cobots or collaborative robots work safely alongside human workers without fences or barriers. They can lift heavy items or assist with tasks like assembling circuit boards. Collaborative robots are a type of AI-powered automation that allows humans and robots to work efficiently side-by-side without reducing safety.

Automated logistics: AGVs or automated guided vehicles use smart navigation technologies to autonomously move materials and products around factories and warehouses without human drivers. When combined with sensors and AI, AGVs optimize traffic flows and product routing to streamline logistics operations. Self-driving vehicles and robots eliminate forklifts and lift trucks driven by people.

Simulation and digital twins: AI and simulation software powered by virtual realities and digital twins of production systems help manufacturers test changes before implementing them in physical plants. This reduces risks of downtime or wasted investment. Manufacturers can evaluate many “what if” scenarios virtually through digital modeling and twinning physical factories with virtual replicas.

There are many benefits of applying AI and automation technologies to manufacturing. Manufacturers that adopt these smart technologies can see:

Increased productivity and higher production volumes. Automated systems and robots can work non-stop 24/7 without rest breaks. They increase throughput and allow much greater volumes than solely human-operated plants.

Higher product quality and consistency. Robots and automated inspections reduce human errors and variations. Quality stays consistent no matter how many items are produced. Precision and repeatability are greater than human abilities alone.

Lower costs through reduced labor needs. Automation replaces human employees for many dangerous, dull, and repetitive tasks. It reduces labor expenses, though initial investment costs require analyzing return on investment timelines. Robots also don’t require health insurance, paid time off, or other employee benefits that drive costs.

Improved workplace safety. Automating hazardous production steps removes humans from dangerous environments and tasks like working with heavy machinery or toxic materials. This improves safety and reduces workplace injuries. Robots do not threaten human safety the way other humans might through accidents or negligence.

Enhanced customization and flexibility. Technologies like 3D printing, collaborative robots, and simulation allow on-demand changes to production. Manufacturers can easily customize outputs, switch between product variants, and scale operations more responsively to changes in demand. Digital computing and smart systems are more adaptable and configurable than dedicated human-operated assembly lines.

Predictive maintenance capabilities. Sensors and AI enable remote monitoring and diagnostics to proactively fix issues before major failures occur. This optimizes equipment uptime and prevents costly downtime incidents. Downtime can threaten production schedules and customer deliverables, so predictive maintenance is crucial for reliability.

Greater energy efficiency. Automated and digitally optimized systems are more efficient than human manual labor alone. Robots and automation eliminate wasted energy from inefficient processes. Optimized logistics further minimize energy used transporting materials and products around plants. Overall energy usage becomes more sustainable through electromechanical automation powered by renewable energy sources.

In conclusion, AI and automation are an industrial