- お役立ち記事

- Catching the Wave of Innovation at the Forefront of Digitalization in Manufacturing

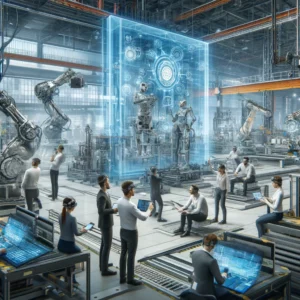

Catching the Wave of Innovation at the Forefront of Digitalization in Manufacturing

The manufacturing industry has traditionally been slower to adapt to changes compared to other sectors. However, we are now witnessing a new wave of digital innovation sweep across factories as they strive to keep up with the rapid pace of technology evolution. Manufacturers that embrace digital technologies will be best positioned to thrive in today’s fast-changing global marketplace.

Industrial digitalization enabled by technologies like the Internet of Things (IoT), artificial intelligence (AI), cloud computing and additive manufacturing is transforming operations on shop floors. Connected sensors are generating troves of real-time data from machines and processes, providing unprecedented visibility into production workflows. This data holds valuable insights that can optimize efficiency, quality control and predictive maintenance when analyzed using AI and machine learning algorithms.

Cloud platforms allow manufacturers to access this operational data from anywhere and share it securely with partners in their supply chain ecosystem. Applications running in the cloud also provide scalability to test new ideas through digital simulations before investing in physical prototypes or equipment upgrades. Additive manufacturing is driving new opportunities in on-demand prototyping and spare parts production. All these digital levers are empowering manufacturers with agility and responsiveness to meet customization demands from customers.

Leading manufacturers are adopting a holistic approach to digitalization called Industry 4.0. This encompasses integrating not just machinery but the entire value chain through digital thread and digital twin technologies. A digital thread connects product design blueprints to production and after-sales support using a common digital back bone. A digital twin mirrors the physical processes and components through its virtual counterpart to enable predictive quality control and remote monitoring.

Data becomes the lifeblood that nourishes collaboration across organizational silos. For example, by tapping into real-time equipment health metrics, procurement can accurately project part replacements needed for preventive maintenance. Simultaneously, R&D gains valuable insights to iteratively improve future product designs based on actual field usage data collected via IoT. Such transparency across functions optimizes inventory levels, lowers downtimes and improves customer satisfaction through faster issue resolutions.

While capital investments are required for sensorizing plants and upgrading legacy systems, the long-term return on investment for digital transformation is compelling. A report by consultancy McKinsey estimates that top manufacturers embracing Industry 4.0 concepts can achieve productivity gains upwards of 30%. Major cost savings also come from reducing waste and eliminating inefficiencies in areas like changeovers, materials usage and energy consumption through predictive analytics of machine performance metrics.

Additionally, becoming a digitally mature manufacturer improves a company’s competitive differentiator. It allows customizing products and shortening lead times to better serve niche market segments. By harmonizing digital threads across the value chain, manufacturers remove communication bottlenecks and information silos that previously hindered collaboration. This strengthens relationships with suppliers and customers. Ultimately, digitization drives top-line growth by empowering businesses to enter new revenue streams and expand into adjacent markets.

However, change never comes easy, and digitization requires an internal cultural shift and workforce upskilling. Legacy mindsets need to transition from a product-centric to a customer-centric and data-driven approach. Employees require continuous reskilling on technologies like data analytics, AI/ML, cybersecurity and cloud platforms to leverage digital tools confidently. Younger talent sees such an environment as attractive and are eager to join companies at the forefront of Industry 4.0 innovation.

Leaders therefore invest in educating current staff through vocational programs and online certifications. They seek fresh perspectives by hiring digital natives passionate about tackling industrial challenges with technology. An innovation-encouraging culture is nurtured where experimentation is rewarded and failures are learning experiences. Digital workshops and hackathons crowd-source solutions from employees as stakeholder buy-in accelerates change management.

The fourth industrial revolution promises tremendous opportunities, but also mandates new ways of thinking amidst constant technological flux. For manufacturers, riding the wave of digital innovation is no longer optional – it is an imperative for long-term competitiveness and survival in tomorrow’s marketplace. Early adopters that transform organizational DNA to embrace technologies will cement their position at the forefront of this revolution. The benefits of improved productivity, profitability and sustainability make digital transformation well worth the journey.

In summary, manufacturers today face a clear choice – adapt to digital disruption or risk obsolescence. Industrial leaders view digitalization not merely as a means for operational efficiencies, but as a philosophy enabling flexible, agile and customer-centric business models. Proactive digital strategies will define which companies truly catch the wave of innovation and emerge stronger in the manufacturing sector of the future.